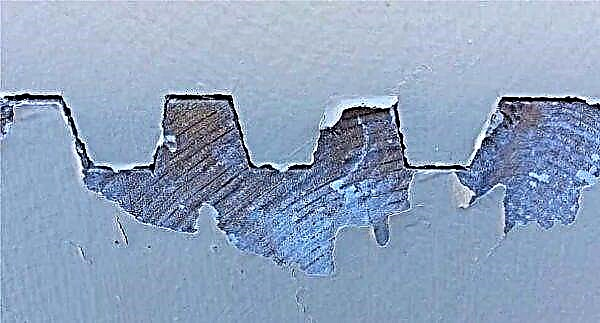

Priming surfaces is one of the stages of the technological chain of finishing work. He is needed often, but not always. First you need to know what composition is needed - when you need a deep penetration primer, and when filling, adhesive. This is important because improper use can cause problems: falling plaster, swollen tiles, etc.

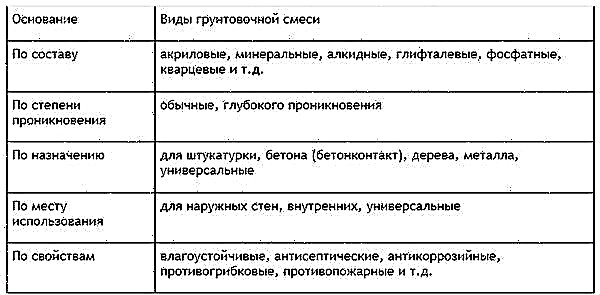

Types of primers and their purpose

In the description of many types of work it is written: a primer base is required. For this stage, special formulations are used, which are called a primer or primer.

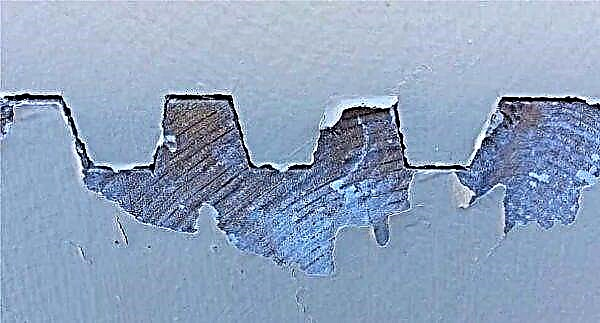

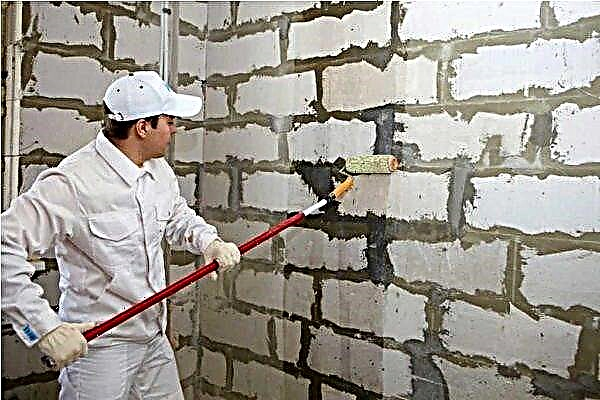

Application of soil - one of the stages of finishing work

What is a primer (primer) or primer? This is a liquid mortar, which prepares the surface for the application of the next layer of finish. Moreover, the “next” can be any, both intermediate and final. Take wall decoration, for example, from bare masonry to painting or wallpaper. First, the wall itself is made of building material. After the soil has dried, plaster is applied. When the plaster has dried sufficiently, apply soil to it, then putty. The puttered surface is also primed, and then after the primer layer has dried, the wallpaper is painted or glued. Such a number of primer layers is not necessary, but an option is possible.

Primer is a liquid composition that provides good adhesion of the layers of the finish to each other

The primer is used when decorating walls, floors, ceilings, and facades. In general, everywhere. There are subspecies for external and internal works, there are which are used both there and there.

Types of primers

As seen from the example, the base on which the primer is applied is different. For example, a concrete wall and foam block, concrete floor, plasterboard ceiling or plastered. They are completely different in characteristics. This means that preparation requires a different, covering the problems of a particular material. To solve each problem there are primers. In general, four groups are distinguished according to the results of the action:

- Filling. These are compounds that reduce the hygroscopicity of the base, its absorbency. Apply to highly absorbent surfaces. Designed to smooth out small irregularities and fill seams in ceramic tiles, plank floors and parquet before puttying. They are applied:

- under the paint to reduce its consumption and to make it go smoother,

- under the plaster so that the wall does not draw moisture from the plaster composition and that it has enough moisture to gain the required strength,

- on the plastered wall under the tile adhesive in order to slightly extend the "life" of the adhesive due to the fact that the liquid will be absorbed more slowly,

- on plaster or putty before gluing the wallpaper so that the surface absorbs glue more slowly, etc.

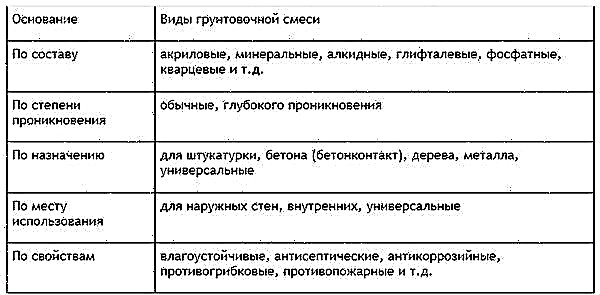

Dividing by different signs. May be useful

Of all the variety of foundations, most of all are acrylic primers. They fill approximately 80% of the market

There are also universal primers. They are the cheapest. The description usually has a pretty solid list of properties. In fact, universal primers contain the least active components. This is also soil, but weaker. This type should only be used if there is no urgent need for a primer. For example, for wallpaper or paint.

The tasks that primers solve

Primers should ensure good adhesion of two layers. This is their main purpose. Most often, this requires adjusting the absorbency of the substrate. The fact is that all finishing materials - plasters, putties, paints, adhesives - are developed for medium absorbing substrates. And there are not many of them. More often absorbent ability to regulate. Sometimes it is necessary to reduce the absorbency, sometimes - to create a sticky film on a too smooth and / or poorly absorbent surface. Here primers and solve this problem.

And also the compositions that lower the absorbency, at the same time improve waterproofing and fight against high humidity. So this is also part of their tasks. And for this they are also used.

Primer is needed to improve adhesion.

Deep penetration primers bind particles on the surface. The compositions penetrate deep into the loose materials to a sufficient depth of 5-7 mm and bind the particles together. Often the “side” effect is a decrease in hygroscopicity and absorbency. Often - this does not always mean, so see the properties in the description of each composition.

Even on the surface after the primer dries, an adhesive film may form, since the non-absorbed composition, having dried, leaves a sticky residue. This improves the conditions for applying the following material. That is, some types of primers increase surface strength and adhesion. Some of the compounds have antibacterial properties, others simply introduce special anti-mold or antifungal additives.

Sometimes a primer is used in order to "make friends" of materials based on cement and gypsum. Without this, there will be no normal adhesion. For example, when a concrete wall or a wall of cement-based blocks is going to be covered with gypsum plaster, the classic and proven solution is Concrete Contact from Knauf. It is applied to almost any mineral base under gypsum materials and ensures their high-quality bond.

Types of primer substrates

So, we came to the conclusion that when choosing a primer it is necessary to focus on the properties of the base. By absorbency, they are divided into three groups:

- With low absorbency and non-absorbent. This group includes concrete surfaces, cement plasters, refractory bricks, sand concrete, polystyrene foam, gypsum tongue-and-groove plates.

- With medium absorbency. Ordinary brick. An ideal foundation that does not need to be applied. But only if the brick has not yet begun to crumble.

Wood is a complex foundation that requires application of soil

How to determine the absorbency of a surface? Apply water droplets to the surface and track the time it takes for them to soak. If it took more than 20 minutes, the surface is non-absorbent, if less than 3 minutes have passed, it is highly absorbent. Everything in between is medium absorbing. In this case, you are lucky and you can do without formulations that regulate water absorption.

Now it’s clear how to choose a primer. Film-forming are suitable for surfaces with low absorbency, and for those with high use primers of deep penetration or filling. Deep penetration is only needed if the surface is dusty, but not loose and does not crumble.

Why is a deep penetration primer needed and how does it work

An indicator for applying a deep penetration primer is a dusty surface. That is, the dust cannot be completely removed. How to check it? A surface is considered “dusty” if a trace remains on the hand after touching it, even after thorough and (if possible) wet cleaning. But only in this case it makes sense to apply this type of primer. In other cases, it will be cheaper to use film-forming or filling.

So for which surfaces is a deep penetration primer used? For chalk surfaces, gypsum plaster before applying paint or wallpapering. Do I need to prime gypsum for gypsum putty? No, they are so good friends. It will be necessary to process all the sheet materials, in which the gypsum acts as a binder: GVL, GKL, tongue-and-groove plates.

If the material is on a calcareous or gypsum binder, it “dusts”. To prevent this from happening, and apply deep penetration primers

Asbestos is also treated with a deep penetration primer, although it is not on plaster, it is dusty. And also silicate blocks before applying a layer of plaster. They also leave a layer on the hand. In general, it seems clear.

Note! The surface to be treated must not be loose. To do this, there is a special primer, which is called strengthening. It also refers to deep penetration soils, but contains a greater amount of adhesives (and is more expensive). If used unnecessarily, the absorbency may be too low, leading to problems.

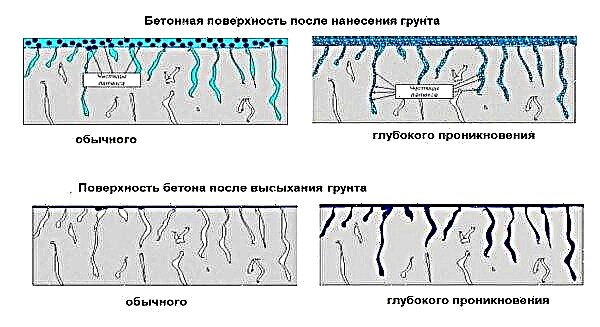

How deep penetrating soil works

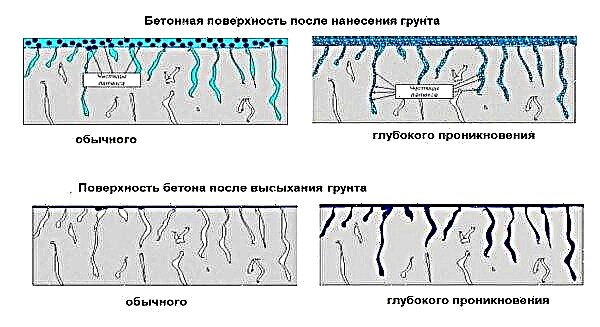

How do deep penetration primers work? They are made on the basis of the same polymers, only modified in such a way that the particles have very small sizes. The difference can be estimated by comparing a soccer and tennis ball. About the same number of times the particles in ordinary and penetrating soils differ. It is understood that smaller particles penetrate deeper.

Deep penetration impregnation or primer works something like this

Very small particles of the polymer dissolve, and with the liquid penetrate through the capillaries deep into the primed surface. After drying, the polymer particles remain in the capillaries, creating an additional crystal lattice there and reducing the porosity of the material (and its absorption capacity at the same time), creating additional bonds between the particles of the material. As a result, after processing the surface ceases to “dust”.

What happens when treating with a conventional primer? Moisture is absorbed into the surface, and larger particles of polymers remain on the surface, only penetrating slightly. After drying, the polymer is concentrated in the upper small layer. This is sufficient for ordinary dust-free substrates. Now, hopefully, the difference between a conventional primer and a deeply penetrating one is clear.

Primer deep penetration: which is better

On the market, as usual, there are many different brands. There are Russian and imported. Of the imported ones, German Knauf and Polish Cerezit are often found. These are companies that have been on the market for many years. There are very few complaints about the quality of their products. Here are just a lot of fakes and you need to know the distinguishing features of authentic products.

Primer for deep penetration: what is needed for what seems to be understandable, but you also need to choose a manufacturer

There are Russian manufacturers who are also on the market for a long time and who monitor quality - these are Eunice, Prospectors, Volma. What is characteristic, the price difference with the "Europeans" is very small - no more than 10-15%. There are cheaper brands, in which the difference is more significant - up to 30%, but the reputation is unstable. And if you look at the description, the difference can be found.

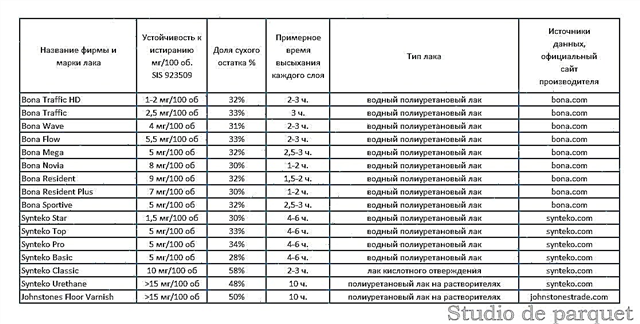

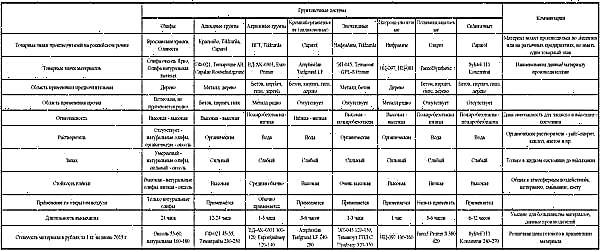

Primers for deep penetration: characteristics, prices, consumption

Title Appointment Type of binder For what reason Under which layers Drying time Consumption Price Notes Ceresit CT 17 / st 17 (Ceresit CT 17) For interior and exterior use Water dispersion of acrylic copolymer Concrete, cement-sand and lime plasters and putties, light and cellular concrete, particleboard, fiberboard, gypsum fiberboard, gypsum plaster screed, bulk floor, gypsum plaster, all types of putties, tiles, paint, wallpaper 2 hours 0.1-0.2 l / m2 10 $ for 10 l It is yellow, for painting or light wallpaper is problematic CT 17 Concentrate For interior and exterior use The same, but the concentrate that is diluted with water 0.1-0.2 l / m2 Prospector Deep Penetration Prospectors For interior and exterior use Styrene-acrylic dispersion with antiseptic additives Concrete and concrete screeds, bricks, plasters, putties, GVL, GKL, TsSP screed, bulk floor, gypsum plaster, all types of putties, tiles, paint, wallpaper 1 hour 0.1-0.2 l / m2 Not suitable for low absorbent surfaces, oil paints and steel Primer Strengthening Vetonit Vetonit.Prim Multi For interior and exterior use Acrylic Dispersion Concrete, plaster, brick, stone, drywall, cellular concrete, foam concrete block, putty, cement surfaces, TsSP, GKL, GLV for painting, waterproofing, floor levelers, for acrylic, silicate, silicone paints 1-2 hours 0.05-0.075 l / m2 11,4 $ for 10 l On weakly absorbing substrates, it can be applied twice GRUNT deep penetration before puttying KSh (10) BIRSS For interior and exterior use Acrylate Concrete walls and ceilings of normal and increased strength (weakly absorbing), GKL, GVL, plasters (except polymer), Before puttying or applying water-dispersion paints 1 hour to tack 0.2 - 0.25 kg / m2 9,5 $ for 10 l Firming KNAUF-TIFENGRUND (Knauf tiefgrund) For interior and exterior use Polymers Gypsum and cement plasters, GKL, GVL, gypsum tongue-and-groove plates, gypsum and cement screeds Putty, paint, wallpaper, tile 3 hours 0.1 kg / m2 12 $ for 10 l Primer composition of deep penetration of Leningrad NPP For outdoor work Acrylic Dispersion Foam concrete, aerated concrete, old plaster, concrete and brick surfaces of gas silicate, slag concrete, plaster Under the subsequent finishing layers 4 hours 0.16 kg / sq.m. 2 $ for 1 liter Do not use on poorly absorbing substrates, lime plaster and whitewash Bolars For interior work Acrylic All types of cellular concrete, cement-sand screeds, plasters (except polymer), fiberboard, particleboard, brick For mortars, paints, finishing materials 1 hour before applying the next coat and 2 hours for other materials 0.08 kg / m2 7 $ for 10 liters Wear gloves, goggles, respirators VD AK 0301 For internal works, for external works (different structures) Acrylic Dispersion On mineral surfaces For painting, tile, wallpaper, putty, for application on concrete floor 24 hours 0.08-0.1 kg / m2 from $ 7.6 to $ 12.7 per 10 liters, depending on type There is antiseptic and old paint Volma Wagon For interior and exterior use Styrene Acrylate Dispersion Tongue-and-groove plates, GKL, GVL, a cement coupler, hard putties, a brick 2.5 hours 0.1-0.15 kg / m2 9 $ for 10 liters On highly absorbent substrates aerated concrete. apply two layers of foam concrete Glims (Glims-Primer Prime) with antiseptic additives For interior and exterior use Brick, concrete, foam concrete, plaster, hard putty, drywall, asbestos cement Stucco, putty, glue, paint 30 minutes to the next layer 0.08-0.2 kg / m2 10 $ for 10 liters Bearss soil M (reinforcing, stabilizing, frost-resistant) For interior and exterior use Acrylic copolymer On plaster, putty, brickwork 20 hours 0.15-0.2 kg / m2 9 $ for 10 l Not recommended for polymer plasters and putties. Unis (Eunice) with an antiseptic For interior and exterior use Polymer dispersion Concrete, plaster, aerated concrete, gypsum plasters, brick. gas silicate, GVL, TsPS ,, tongue-and-groove plates, For painting, plaster, wallpaper 30-40 minutes to the next layer and several hours for subsequent work 0.15 kg / m2 6 $ for 10 l Works with wood, does not allow efflorescence on brick 2-in-1 Deep penetration primer TEKS Universal For interior and exterior use, for walls, floors, facades Polymer Wood, concrete, drywall, putty For painting, wallpaper 30-40 minutes 0.07-0.2 kg / m2 Expert Perfekta For interior and exterior use Polymer Concrete, brick, cellular concrete, cement and gypsum plasters and putties, GKL, GVL, TsSP, paint, wood, tile Plasters, putties, tile adhesives, water-based paints and varnishes, self-leveling floors. 1 hour 0.15 - 0.2 l / m2 $ 7.3 per 10 liters Optimist (antibacterial) For interior work Acrylic latex Concrete, gypsum brick, gypsum, cement plaster, mineral and wood surfaces Varnishes, paints, including water dispersible 30 minutes to the next primer coat and 2 hours complete drying 0.1 - 0.25 l / m2 $ 6.3 per 10 liter canister Optimum Leningrad paints For interior use, for walls Acrylic Concrete, plaster, drywall, brick, wood Waterborne paints, tile adhesive, wallpaper 0.07-0.2 kg / m2 $ 4.3 for 5 liters As you can see from the table, to say that there is no difference between more expensive and cheaper brands, it will not work. Even according to the description of the surfaces on which the composition is applied. Surfaces are significantly larger in more expensive compounds. Well, you have to look at the quality. But usually cheaper ones are used for applying paint (if it is not expensive), for gluing wallpaper, etc. For more critical areas - such as plaster, putty, on complex substrates - they prefer not to take risks and take products from trusted companies. Quite a reasonable approach.

Application Rules

The rules for applying any type of primer are similar. A deep penetration primer is also applied to a dry, clean base. Dry is a residual moisture content of the order of 3-5%. Clean - without oil and mud stains, exfoliating materials. That's just "dust free" - this is not for this case. Although all dusty particles must be removed. If dusty work was carried out, we pass the walls with a brush, sweep the floor, if necessary, wash and wait for drying.

A marker or application control is a pigment that allows you to control the process.

Further, the primers are applied to warm substrates. We look at the minimum allowable temperature in the description, but usually it is not lower than 10-15 ° C, but there are frost-resistant compounds. They can be applied to surfaces with a temperature of + 3 ° C. Note. This is the surface temperature.

Compositions can be applied with a brush, roller, spray gun, spray gun. Some of them contain a coloring pigment that allows you to control the application. But in some cases - under the paint or light wallpaper - the presence of pigment can interfere, as it can distort colors. Therefore, under the finishing light materials we take a transparent or white primer.

The principle of operation and soil composition

The tool is designed to remove dust and strengthen the base. Unlike other primer mixtures, its particles are able to penetrate into the material to a depth of 10 cm. They bind a loose structure and create a layer on the surface that increases adhesion.

The recipe for different products may vary significantly. But its basis is made up of the following components:

- Water. It is a diluent of the solution. Its share is about 80%. Regulates the consistency of the mixture and the number of active components per unit volume.

- Acrylic. Resins play the role of a binder. They strengthen the material and create a film on the surface with high adhesion.

- Polymers They give the liquid enhanced characteristics of capillary permeation. They are responsible for the ability of particles to be absorbed as deep as possible into the base.

It is acrylic primers of deep penetration that have become the most popular and in demand among masters.

But besides the main ones, there are additional components. They expand the scope of the soil and give it new properties.

- Antiseptics. Antifungal components. They are used if mold, fungus and other bacterial media are present on the surface.

- Silicone agents. They repel water, give the base waterproofing properties.

- Latex. Increases adhesive performance, is used for increased requirements for adhesion of the layers to each other.

Priming agents with additives simultaneously perform several functions, therefore they are called universal.

On sale there are components from which you can prepare primers with your own hands. They will cost less than finished factory products. But good results can only be expected if the resulting mixture complies with GOST.

Principle of operation and application of a primer

After applying the primer to the surface, the liquid completely impregnates it. When dried, small balls of acrylic resins stick together and form long threads that penetrate the base to a considerable depth.

The primer is the link between the base and the finishing materials, it strengthens weak and friable surfaces, so that their absorbency is significantly reduced, smoothes out small irregularities and improves adhesion. This makes it possible to evenly and economically apply the finishing layer.

There are various types of impregnation suitable for different surfaces.

The use of the solution is relevant before:

painting of cement plaster - prevents shedding of the base,

sticking wallpaper on a base with lime - will not allow whitewashing to crumble as a result of temperature fluctuations or a change in humidity level,

painting brick walls.

View productsComposition, main features

The deep penetration primer usually contains the following substances:

acrylic resins - are a connecting element,

polymers - increase the depth of penetration of the soil.

Depending on the manufacturer, other substances may be added to the primer:

latex - increases grip,

silicone - gives the surface water-repellent qualities,

fungicides - add antiseptic properties to the composition.

Additional elements determine the purpose of the primer and the time required for complete drying. The fluid flow rate ranges from 100-200 g per 1 m2 of surface and depends on the absorbency of the base.

Characteristics that contribute to the growth of primer popularity:

high vapor permeability and moisture resistance,

excellent adhesion

frost resistance up to -15 ° C,

formation of a transparent layer after drying,

increased resistance to mechanical damage and chemicals.

In addition, the use of a primer can significantly save finishing materials.

Universal

This deep penetration primer can be used for almost all internal and external works; it treats both vertical and horizontal surfaces. The solution has the following advantages:

goes well with different types of substrates,

has a strengthening effect on the surface,

can be used on underfloor heating

it is easy to determine how much of the surface has already been treated.

This environmentally friendly substance is very popular among consumers.

Acrylic

It can also be used for processing almost all bases, it does not matter if it is wood, drywall or brick wall. Advantages of this primer:

interferes with the reproduction of microorganisms harmful to human health,

reduces the consumption of finishing materials.

In addition, the absorption capacity of the treated surface is reduced.

Antifungal

The appearance of fungus or mold in residential buildings can significantly impair the health of the people living in them. To prevent such problems, antifungal agents are created. They can have any basis - mineral, acrylic, alkyd, but fungicides are mandatory components. Such a primer is usually used to treat surfaces already affected by pests.

Facade impregnation

Most of the facade surfaces are made of mineral materials, which include silicate bricks, plaster, gas silicate blocks. Such substrates easily interact with water and other substances, so a deep penetration primer for facades should have a silicone or silicate base.

Latex primer

The basis of this impregnation consists of water and polymer. It is used to hide small flaws in a metal, wood or concrete surface - stains of grease, tar, rust or soot. Also, such compounds are well suited for processing substrates in rooms with high humidity. Quite often, latex is used in combination with alkyd soil.

Rules for choosing a deep penetrating primer

The primer should answer, if not all, then at least most of your requests. When choosing it, you should pay attention to the following factors:

what kind of work requires a tool - facade or interior. In the first case, it is necessary to acquire impregnations that are resistant to low temperatures. When working inside the building, preference should be given to soil without a strong odor. For processing rooms with high humidity, it is best to use an antiseptic mixture,

material of which the base is made. So, for concrete, acrylic or alkyd impregnation is suitable, for wood - antiseptic oil, and for tile - antifungal,

the period of complete drying - when conducting internal work it is very important that the drying of the soil takes place in a short time, especially if you need to apply several layers,

finishing material. For different types of finishes, you can choose a special impregnation, the purpose of which is indicated on the label. Or use a universal primer that is suitable for all finishing materials,

volume - in order to calculate the right amount of funds, you need to know its consumption per m2 and the area of the base that requires processing,

manufacturer and customer reviews are equally important factors. It should focus on the products of enterprises that are well established.

In addition, it is worth paying attention to the mark whether the product meets the requirements of GOST or is it produced according to the technical specifications.

Application Tips

It is not difficult to use a primer, this does not require special skills, you only need to follow certain rules:

Before processing, the base should be cleaned of construction debris, dust and grease stains. A vacuum cleaner, brush or whisk will help to get rid of dust, you can remove peeling old coating with a hard spatula.

Metal elements present on the surface are recommended to be freed from rust.

Apply the solution to the floor and walls with a wide brush, while the layer should be uniform. It is worthwhile to apply the roller only when processing smooth surfaces.

On large areas for applying the composition, it is better to use a spray gun - this will significantly speed up the processing process. Also, this method can be used when applying the product to the ceiling.

On the base with a large number of pores, the composition is applied in 2-3 layers, and large cracks and crevices are pre-closed.

Each new layer should not be applied before the previous one dries.

There are concentrated impregnations in which, in order to obtain the required consistency, it is necessary to add water or a solvent. As a rule, this is done in a ratio of 1: 1 or in the ratio indicated by the manufacturer.

If gypsum putty is used as a finishing material, then a deeply penetrating primer is applied twice - before and after puttying.

The properties

The basis of any deep penetration primer is a latex emulsion diluted with water. Latex has the ability to penetrate deep into the pores of the base, strengthen the surface and cover it with a thin layer of film. Actually this feature is used in decoration.

It is very superficially believed that the primer improves the adhesion (adhesion) of the layers to the base. In general, this is a true statement, but a little amateurish. The primer indirectly affects adhesion, let's see why. In fact, latex emulsion does two important things with the surface: strengthens it and thanks to the thinnest film reduces absorption. In turn, strengthening and limiting absorbency affects adhesion. Having well understood this principle, it is possible to accurately determine whether it is necessary to prime in a particular case or not.

We analyze these two properties separately. Strengthening the surface. When the surface is loose, dusting and collapsing from light mechanical impact, the primer will be very useful. It penetrates deep beneath the surface and will bind loosely adhered particles, thereby forming a tear-resistant base. With a sufficiently strong surface, situations are often encountered when it is covered with dust and removing dust is problematic for one reason or another. Therefore, the soil will also be useful: it will bind the dust particles to the base, as if sticking them and making them one with the surface.

Absorption limit. Many surfaces have sufficient strength, but are too porous and actively absorb water. Often this interferes with the subsequent finishing: the applied mixture can dry out too quickly and interfere with convenient application. Wallpaper glue will dry faster than the wallpaper is glued, gypsum putty will start to set faster than it will even out. In this situation, the primer will help us solve such problems.

And it also happens that the surface of the base is durable, dust-free and practically does not absorb water. Concrete and many other surfaces usually have such properties. In these cases primer is optional!

Often, a generously primed surface can interfere with the quick drying of the layers. This does not mean that the primed surface does not breathe and does not allow moisture to pass through. It completely skips and breathes. But much less than in vivo.

Soil limits not only water absorption, but also the diffusion of the substance - the penetration of cement particles from the applied solution during plastering into the base. This reduces adhesion at the molecular level.

With cement-based solutions, an interesting situation is generally: on the one hand, when applying the solution, it is necessary to limit the water absorption of the base. This is necessary so that the applied solution does not dry too quickly, because for a full-fledged reaction of cement moisture is required for a long time. On the other hand, this same cement will penetrate less into the primed surface and, as a result, adhesion to the base will be weaker than with the unprimed surface. In such situations, you should be guided by specific operations, examples of which we will consider below.

General information

Primer compositions perform the following functions:

- Reduce the absorption of finishing materials, as they fill the pores of the surface. As a result, paint, varnish or glue are not wasted, but remain on the surface of the material.

- Increase adhesion (the ability of materials to adhere). Although it is worth making a reservation: if we are talking about cement plaster, then the adhesive properties will become worse, since the cement milk does not absorb into the pores - because they will already be filled with a primer.

- Strengthen the base, penetrating deep into the structure of loose and porous surfaces. Soil, as it were, binds together the disparate elements of the base. Reduces the likelihood of shedding of plastered surfaces, peeling whitewash, chipping mortar at the seams, etc.

Specifications

The properties of deep penetration primers vary depending on the specific composition. However, some technical properties are similar for all soils.

Note! Some manufacturing companies offer the market concentrated anhydrous mixtures. Such compositions are diluted with water immediately before use in proportions from 1 to 1 to 1 to 5.

The primer density indicator is equal to the density of water (kilogram per cubic decimeter). In some cases, the density of the mixtures may slightly exceed the density of water.

The approximate consumption of a deep penetration primer can range between 100 and 200 grams per square meter.Moreover, the same soil can be consumed in different quantities, depending on the absorbing capabilities of the substrate.

The drying time of the primer depends on its composition, namely on the percentage of the water base. Well-soaked materials dry for 1 to 3 hours. Optimum indicators for quick drying of the surface: air temperature - about 20 degrees above zero, atmospheric humidity - 70%.

Fields of application

As mentioned above, deep-penetrating soils are primarily used to strengthen loose and porous substrates. These materials include the following materials:

- Cement plaster before painting. Priming helps to avoid surface shedding and also reduces the absorbency of the material.

- Brick for painting. Soil protects seams from spalling.

- Wallpaper sticker on lime whitewash. Due to the interaction with acrylic resins, whitewashing will not peel off due to changes in humidity and mechanical loads.

In some cases, the use of deep-penetrating primers is at the discretion of the master:

- If the plaster is applied to the shell material, the spray (the rough layer of the plaster) will hold well on the surface, despite its high porosity.

- Monolithic concrete, concrete screeds, aerated concrete, oriented particle boards and particle boards can be treated with quartz sand primers. Although such compositions do not penetrate too deeply, in spite of this, the surface acquires a pronounced roughness, which ensures excellent adhesion.

Primer instructions

The following is a sequence of steps for applying a primer:

- We clean the surface from pieces of peeling paint or plaster. We use a hard spatula. If we are talking about plaster, we tap it with a small hammer or pickax to find voids.

- We clean the base from dust and dirt with a brush or vacuum cleaner.

- Apply the primer using a brush or spray can. If the floor or walls are very smooth, it is preferable to use a roller with a long pile. Surface treatment is carried out exclusively at positive air temperature (at least 10-15 degrees above zero).

Helpful advice! If there is no factory-made sprayer, the device can be borrowed from a bottle with a wiper.

Further actions depend on the goals and type of surface:

- in the case of plaster we put beacons,

- before applying the putty, remove the protrusions from the surface and level the pits,

- if you have to paint, putty small defects, etc.

Separately, it is worth mentioning the use of deep-penetrating primers with gypsum putty.

Typically, such compositions are applied 2 times:

- First, they process the surface before puttying.

- The second time the primer is applied after grinding, just before painting.

If a deep-penetrating composition accidentally lands on a surface not intended for priming, you can remove it using such means:

- soda diluted in large quantities of water,

- acidic means of household chemicals "Cillit",

- detergent "Mr. Muscle",

- Acetic essence concentrate.

"Mixonit GR 43"

The primer is excellent for preparing the foundation before laying tile or facing stone.

Technical characteristics of the composition:

- absorption depth up to 10 centimeters,

- the absence of any odors

- vapor permeability

- the presence of antiseptic and flame retardant properties.

"Pro-acryl-primer"

Latex and acrylates are used as bonding agents in the primer. Also in the ground there is an antiseptic substance and a foam quencher. Thanks to antifoam, the substance does not foam when stirred.

The primer is applicable not only to mineral bases, but also to wood. "Pro-acryl-primer" can be used both for internal work and for strengthening the facade, since latex is included in the composition, which increases the resistance of the material to moisture.

"Optimist"

Priming compound “Optimist” is made on the basis of acrylic polymer and is suitable for processing both internal and facade surfaces. Due to acrylic, the substance penetrates deep into the structure of the material, while providing excellent adhesion. Also, "Optimist" contains an antiseptic that prevents mold and mildew.

A special deep penetration primer for Optimist concrete is available. It is suitable for the treatment of concrete and brick surfaces. If desired, the composition can process plaster, drywall sheets and wood. After applying the soil on a dried surface, a thin but durable transparent and colorless film appears.

Technical data of the optimist primer:

- penetration into the surface - up to 5 centimeters,

- the consumption rate of the material is from 100 to 250 milliliters per 1 m2 (the specific figure depends on the type of surface),

- final drying time - 2 hours,

- the color of the liquid solution is white,

- the composition can be stored for no more than a year at a temperature of 5 to 30 degrees above zero,

- when applying soil, the ambient temperature can be from 5 to 30 degrees above zero.

"Ceresit"

This brand can be called the most common choice among masters. Products are of high quality and complex, but effective composition.

"Ceresit" is used to treat any surface with an absorbent base. The composition improves the adhesive quality of materials, binds dust deposits, strengthens the base. Also, “Ceresit” does not allow to dry thin leveling solutions, improves the spreading of floor paints and materials and prevents their bubbling.

To work with highly porous substrates, the emulsion is diluted with water in a ratio of 1 to 1. Ceresit is applied in several layers.

The answer to the question of how much this composition dries is ambiguous. Due to the saturation of the composition, this primer dries for a rather long time - from 4 to 7 hours. If we are talking about gypsum and wood surfaces, the drying time of each layer can reach up to a day.

- soil base - acrylic copolymers,

- the color of the composition is light yellow,

- the consumption rate of the material depending on the type of coating is from 100 to 200 milliliters per square meter,

- the optimum temperature when applying the composition is from 5 to 35 degrees above zero,

- soil must be stored in unopened packaging for 1 year.

To prevent fungus and mold, the Ceresit CT 99 deep penetration antifungal primer is available. The product produces in a package of 1 liter. Primer is used as a separate layer together with a deep penetration primer.

It should be remembered that deep-penetrating soil is not omnipotent: it can strengthen the loose base, but it will not fix a clearly peeling area. When purchasing a primer, it is recommended to pay attention to its compatibility with one or another base.

Appointment

As we have already found out, the primer is intended to strengthen weak, crumbling bases and dust binding, as well as to limit absorption. By and large, all surfaces can be primed before applying plaster, putty, painting, wallpaper and other things. Consider some common examples of soil application, as well as those cases in which a primer is not needed.

Before plastering. If gypsum plaster is applied, then any surfaces must be primed. Even a strong, non-absorbing concrete base - this is how we will bind the dust. At the same time, if it seems possible to dust the concrete well - the soil can be omitted. Cement plaster is another matter - according to the technology, the first step is spraying and therefore the soil will be superfluous, even when plastering aerated concrete and foam blocks. However, many plasters do not work according to technology and often exclude spray from the process - in this case, it is recommended to prime the surfaces.

Before puttying. When applying gypsum putty, due to the high sensitivity to water absorption of the base, it is recommended to prime any surfaces. An exception may be concrete surfaces if they are well dust free. The same applies to drywall - it is not necessary to prime a well-dusted surface. What can not be said about gypsum fiber - it more actively absorbs moisture and is dusty enough, how much does not dedust. On the other hand, if you are not sorry for the material and time, any surfaces can be primed before gypsum putty.

Another remark about GCR - cut joints are still better to be primed. Gypsum is exposed on the cut edge, and it has good absorbency. Priming factory edges is undesirable, more in the article.

Before applying polymer and other putties that are not particularly critical to water absorption of the base, one should focus on dust removal (dust binding) and strengthening weak surfaces. If the surface is not dusty and durable - there is no need to prime.

Novice’s eternal question: is it necessary to prime between putty layers? Adequate answer - no! Between the layers of polymer putty there is definitely not, when using gypsum - in more detail here.

Before pouring screeds. Actually here you should focus on dust removal - usually the screed is poured onto a concrete floor, so the absorption is small. That is, it is necessary to prime only for dust removal, if necessary (there is no possibility to dust well). If there is an old screed on the floor or heavy traces of mortar - the soil will be acceptable.

The diffusion of cement particles into the base should not be taken into account, because for the screed, it is not so much adhesion to the base that is important as the strength of the intrinsic layer.

I would like to separately highlight bulk floors: in these mixtures, a slightly different chemistry occurs, in comparison with a conventional solution and therefore it is necessary to follow the manufacturer's recommendations. This does not apply to conventional sand concrete mixes.

But the surface of the cast screed or the self-leveling floor must be primed unambiguously! This will strengthen the layer from the capping and prevent excessive dusting.

Before wallpapering. If you glue wallpaper on a putty surface - it is necessary, since grinding should inevitably be followed by puttying. But dusting putty in other ways after cleaning is problematic, regardless of the type of putty mixture.

When removing old wallpaper and sticking new ones without glossing over defects, there is no need for priming. The surface is already saturated with old wallpaper glue, thus the base does not absorb plenty of water.

Before painting. When applying water-based paints with a primer, there is no need to rush. Much depends on the degree of dullness / glossiness, on generously primed surfaces unpainted areas may appear. Therefore, the soil should be abandoned altogether or diluted with water. I repeat that it all depends on the paint and in general, high-quality painting is a science.

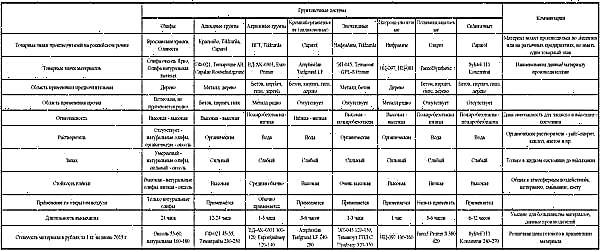

How to check the quality of the primer?

There are a great many different types of deep penetration grades on sale. A low-quality product is very common: after processing with such a composition, the surface continues to actively absorb moisture. It is not always possible to determine by eye whether a strong film has formed on the surface or not.

After some primers, for example CT17, the light surface darkens noticeably. However, after priming with some formulations intended primarily for finishing work, the treated surface does not visually differ from the unprimed one.

There is a simple visual test that will help distinguish real soil from an incomprehensible white "slurry." For the assessment you will need a clean, uncoated a surface that normally absorbs water and darkens. Walls plastered with gypsum putty, such as fugen, are excellent for this. On polymer putties the effect will not be so noticeable, however, a similar assessment can also be made on them.

So, with the test compound we process a small area, literally a few brush strokes. Due to the fact that the surface has slightly absorbed the soil, this area will darken. Now you should wait a bit to dry (usually no more than half an hour), when the spot brightens.

Well, then treat the wall with the same composition with a roller, on top of our spot and more. With a high-quality primer, a pre-primed area will be very different visually from the entire surface. Our spot will not darken, because the site does not actively absorb moisture. If the spots can not be distinguished, then you use white water with an acrylic odor.

Concrete contact

Many smear concrete contact wherever there is a hint of its use. In fact, only one useful place of application was found in this soil. These are places where it is not possible to remove old paint. In other places, concrete contact can often be not only useless, but also harmful.

Someone applies it before pouring screeds, not suspecting that many variations of this product are not resistant to alkali, and the solution is an alkaline mixture. As a result, the layer of concrete contact simply dissolves under the aggressive action of cement.

Someone applies this primer to smooth concrete before plastering. This is somehow justified when plastering with gypsum mixtures. However, in my experience, gypsum plaster adheres well without concrete contact, with proper preparation of the foundation. Concrete contact is relevant when it is not possible to peel off all the paint, when the alkyd paint is removed by the hot method - although the paint is removed from the surface, all the pores in the paint.

As a result, it turned out a bit too much text, but now you can immediately understand the purpose of the soil in a particular situation.