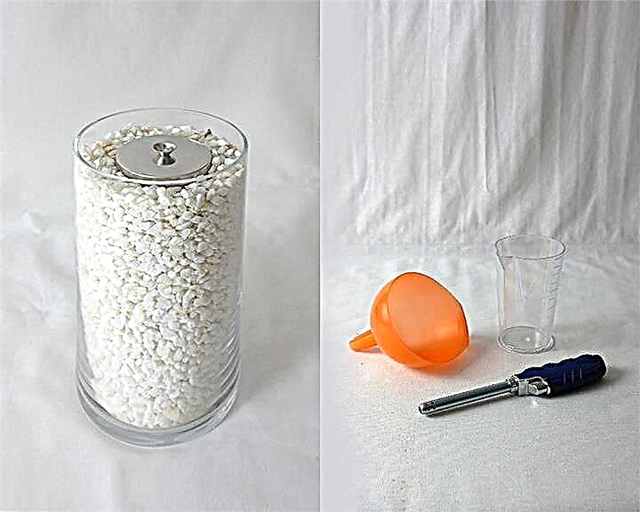

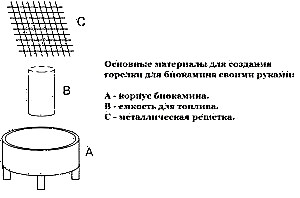

How to make a bio fireplace with your own hands? It’s easy just if your hands grow from the right place. For the manufacture we need the following tools, materials:

- Glass. Pieces are at the glass cutting points. You can take an old aquarium.

- Glass cutter.

- Silicone sealant (glue glass).

- Stainless steel mesh.

- Box of metal.

- Small stones.

- Fuel for a biofireplace.

- Wick (piece of cord).

- A glass of metal for fuel.

Variety # 1 Board

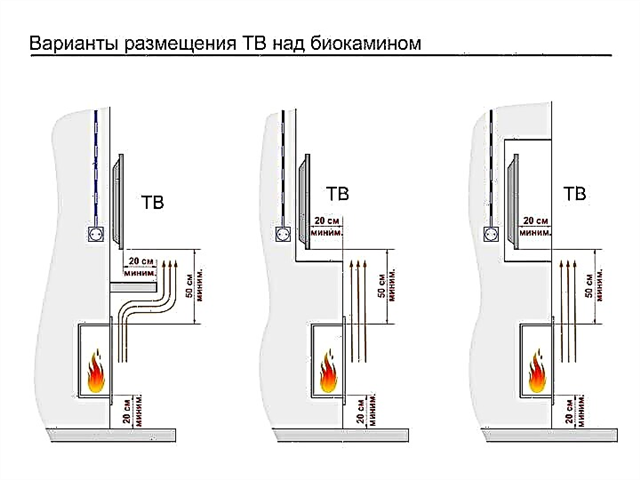

First, figure out how to make a bio fireplace on paper. Sketch a simple drawing with dimensions. When designing a tabletop fireplace, consider the moment that the distance from the burner to the nearest glass should be 16 cm or more. If the burners are 2 or more, then the distance between the burners is also more than 16 cm. As a result, we get a table fireplace on paper.

The manufacturing process will look like this:

As a basis, we took a box of metal of a certain size (according to the drawing). Under it we will customize all other components.

Often fuel is sold in plastic containers. She does not suit us. We take an iron glass. We pour fuel into it.

We take a grid of iron. Cut it to the size of a metal box. It is better to take 2 layers of mesh. On the grid, over the entire area we sort out the stones. Stones are not only a beautiful accessory for our heat generator. They excellently accumulate, give off thermal energy. They do this evenly, throughout the covered area.

We take an ordinary cord. Cut off a piece of the desired length. Immerse the cord in a glass with fuel, ignite. With the help of simple manipulations, the device of a biofireplace is made quickly. Above we received the answer to the question "How to make a burner for a bio fireplace with your own hands"?

Variety # 2 Wall Mounted

This type of heat aggregates has a flat, elongated shape. This shape makes it easy to mount the structure to the wall. The front of the device, for safety reasons, is closed with glass. The side walls of the device can also be made of glass. The back wall is made of non-combustible material. Usually it is iron, decoded in various design options. Hanging such a fireplace is easy. Special fasteners are screwed to the wall, then the fireplace is fixed. The device does not pose a fire hazard, because the case, walls are slightly heated. Due to poor heating, a person will not get a burn by touching the body.

The manufacturing principle is the same as the desktop device. You make a drawing by specifying dimensions, materials. Next, make the product itself, hang it on the wall. The production of bio-fireplaces at home is a simple, not troublesome business.

Variety # 3 Outdoor

We put this species on the floor, on its own legs. In fact, this is a desktop fireplace, only on a large scale. Can be put on the podium. The bottom will not be very hot. Based on this, the device can be hoisted on any straight, level surface. Size, shape are different rooms. A big plus of this device is mobility.

Drag to a new place - a matter of 1 minute. You can quickly heat any room by simply moving the unit to a new place. We see that making a bio fireplace with your own hands is easy, simple.

The simplest fuel cell model

A simple-do-it-yourself burner for a biofireplace will be done this way. We take a container of stainless steel. The wall should be from 2 mm. Depth of capacity is 5 cm. The sizes are arbitrary, according to your drawings. Appearance is not important. This element is hidden from the eyes of strangers. But it must be a solid, strong element. Biofuel is poured into a tank, a glass. Insert the wick. Take out through the net to the outside. A cord soaked with flammable liquid lights up, emitting light and heat.

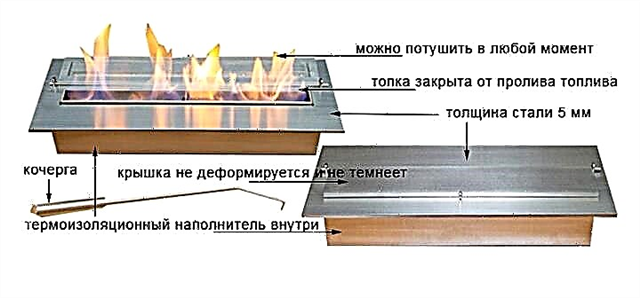

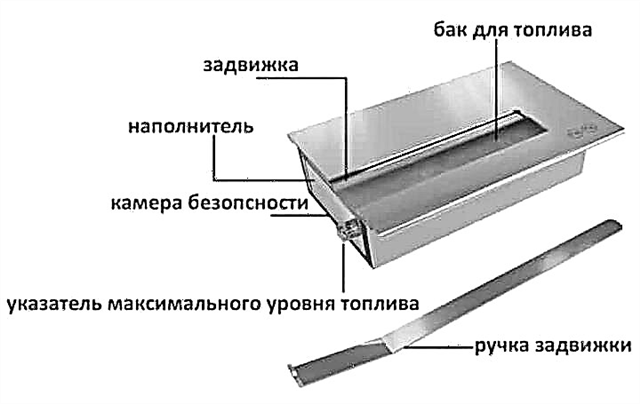

Two-chamber burner with perforation (cuts)

This design option is usually done in the factory. It is distinguished by fuel economy. This is due to a decrease in the burning area. Fuel consumption is reduced.

We take a bath, a box from a stainless steel. The sizes are arbitrary. It is possible as in the previous version. We cut the plate along the length of the body (on the inside). The plate should be the same thickness as the body material. We calculate the width using the formula: SH = Vs - 1.5 + 2xRs (where Vs is the width inside the bath and Rs is the depth of the bath). Plates bend at right angles from long edges. This is done to get legs in depth equal to Rs. We have obtained an element along the length of the bathtub, 1 cm narrower than its width along the profile resembling the letter P.

On one of the legs of this letter P, we make incisions, as on a comb. We set the U-shaped design so that the gap between the slots and the wall is 1.5 cm. We fill the tank with fuel. Ignite. The flame will be located only in a narrow strip of 1.5 cm. The fuel below will not light up. Oxygen access is limited. Lack of fuel is not expected. It will seep through the slots. To quickly extinguish the fire, make another plate that will cover the fire.

To fuel burned to the end, the tank is tilted towards the working surface. This can be done by mixing fuel with gypsum. Next, tilt the resulting mixture in the direction of the workplace. The mixture hardens. We get a great result. In this case, the leg of the P-design must be shortened. This is necessary to give full horizontal structure. You can make a tank with a double bottom. The finished burner is placed in an additional, larger tank. The edges of the upper tank will close the tank elements from below.

The simplest device with a filler

A tank with a P-profile must be filled with filler. Usually it is mineral wool. Basalt fibers must be replaced with cotton on an acrylic component based on factors:

- Hygroscopicity. It absorbs moisture well.

- Fiber filler has better vapor permeability. Vapors of alcohol will circulate without problems inside the filler.

- Soft cotton wool burns evenly for a long time.

- During the production process, such wool does not abuse various chemicals.

- If there are difficulties with the supply of acrylic wool, find a similar one, only softer. Soaked cotton wool will burn more slowly, increasing the overall burning time.

- We understand that a biofireplace with their own hands is going without worries, hassle.

An even simpler design for you. An iron mug will do. You can pick up a jar. We put the absorbent in the pan. There is no need to ram. We fill the filler with fuel. Upstairs we put an iron net, a cover with holes. Next, set it on fire.

DIY step-by-step instructions for a bio fireplace

We assemble a biofuel fireplace using the step-by-step manufacturing instructions. Everything is simple. Even a high school student will do it. Getting down.

- Pre-prepared pieces of glass of the right size are glued together. Silicone sealant is best suited for this purpose. For a day we forget about our product. It must thoroughly dry.

- The base of the structure is usually made into a rectangular or square base.

- Pour fuel from plastic containers into metal vessels (tin can, iron cup).

- Dip the wick from the cord into the burner.

- We put a metal grid on top.

- Pour stones on the grid.

- A biofuel fireplace is ready for launch.

The choice of fuel for biofireplaces

At first glance, choosing a fuel seems like an easy task. But this is not so. The fireplace you gathered once, forever. You will buy fuel regularly. This issue should be taken responsibly. An important point. The fuel must have the prefix “bio” in its description on the package. There are fluids from wood chips, beets, potatoes. Such a liquid does not form toxic combustion products after combustion. Such a device is completely safe for humans. The flame sways evenly and beautifully.

This effect is completely absent with other types of fireplaces.

Rules for the safe use of a biofireplace

- Rules for the safe use of a biofireplace

- Do not leave open fire unattended.

- The fireplace is ignited only by adults. No children allowed.

- You can not put a fireplace near the fan, in a draft.

- During burning, the fireplace is not allowed to be moved. Moving is possible after complete extinguishing of the fire.

- It is forbidden to place a fireplace where combustible substances are stored. Gasolines, varnishes, paints, other liquids.

- Fill the tank with fuel only through the funnel.

- Do not place any objects on the device.

- It is forbidden to burn any type of fuel, except for a specially designed type.

- You can not make changes to the design of the system without figuring out what and how to do.

- Never add fuel to the combustion process. A fire will happen instantly.

- Do not smoke when refueling.

- Spilled fuel must be wiped off. Otherwise, a fire may result.

- Do not bend over the fireplace. Do not hold hands near the fire.

- Do not cover the structure with anything. This will cause a fire.

- You need to extinguish the fireplace flame with a special metal plate.

- To refuel again, wait 15 minutes after extinguishing the fire. The device should cool.

- It is forbidden to remove the tank while the fire is burning.

- It is forbidden to use ordinary matches, lighters. You need to use special accessories for these purposes.

- If the fuel does not burn, it has a low temperature. Let it warm to room temperature.

- Closer than 1 meter from the fireplace, nothing should be.

- As you can see, the device biofireplace, a simple device. Operating rules are also easy to follow.

Biofireplace in the interior: designer tips

A biofireplace will fit perfectly into the design of the room. The living room, kitchen, hall will well fit our novelty into your interior. The flames are the same everywhere. However, it is in our power to choose the design of the fireplace lining. The main point, the size of the room. In the big hall, you need a big fireplace. The area of the hall allows you to put a fireplace near one of the walls.

Small fireplaces will not fit in the room. They will get lost in the big hall. For the bedroom, small, desktop models are suitable. For large, there simply will not be room. Kitchen, the usual place for a fireplace. It is set in the dining area. You can also at the bar, if space permits. Can be put in special niches. You can integrate a fireplace into any room design.

Primary requirements

First of all, it is necessary to decide which device we need: a large bio-fireplace for installation on the floor, a suspended version, or a very small device made for use on a table, work or magazine. For work, we will need design drawings, sketches and sketches of the general view of the biofireplace.

Note that all biofireplaces work on the same principle, and the main differences are their appearance and functionality (control, sound).

As the main criterion for production should choose quality. That quality will serve as an excellent guarantee for long-term use of the device and will ensure maximum safety of its operation. Thus, even a self-made bio-fireplace burner should work properly, without failures, because the heating unit of the device is the most important.

When designing and creating a burner for a biofireplace, you should pay attention to the following aspects:

- When choosing materials for the biofireplace firebox, it is always worth starting from high-quality, fireproof options. In particular, hardened metal will be the optimal solution for the burner, since along with excellent heat-resistant characteristics, it is also sufficiently malleable for processing. Whatever you choose from, always analyze safety factors and ease of working with the material. In this regard, ceramics are beautiful, but not so accessible for processing.

- Developing a drawing of a biofireplace burner, experts advise to pay special attention to the furnace and the fuel storage tank. It is advisable to make compartments for bioethanol with a thick bottom and walls to prevent possible disturbances in the system. Your biofireplace must be made safe for use, to minimize the likelihood of deformation of its body, to exclude the possibility of pouring fuel from the tank.

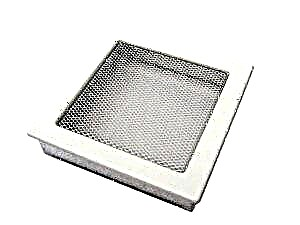

- In addition to safety, other nuances in the operation of the device should be taken into account. For example, to evenly distribute the fire inside the apparatus, a metal mesh can be placed on top of the burner. It will additionally become the basis for decorative elements. It is also important to consider the distance from the burner to the walls of the bio-fireplace protective shield. It is advisable to withstand it at least 10-15 centimeters. If the biofireplace device involves several burners, then they must be placed at some distance from each other.

- The internal device of the burner for a biofireplace is simple, here a wick plays a very important role, which connects the fuel unit of the device to the external part. During the operation of the device, bioethanol impregnates the wick tissue, thereby rising from the reservoir to the focus. You can use a lace as a wick, carefully lay it inside the device and bring it out in an inconspicuous place outside, hidden by decorative elements.

- When assembling the device, carefully check all the fasteners for reliability. If the assembly diagram is not compiled correctly, you should improve the design of the device and consider a new option.

- When the biofireplace firebox is assembled, it is necessary not only to visually evaluate the result obtained, but also to make sure that there are no deformations of the device that appeared during assembly. If there are no visible violations, then you can continue to work on preparing the device for work.

- Thinking over the biofireplace device and developing the drawings, you should decide on the appearance of the device. An important role here will be played by a portal or a protective screen made of refractory glass, constructed in such a way that the view of the fire will be from all sides and angles.

How to do it yourself

Many people prefer to make decorative elements for decorating their home on their own, and a burner for a biofireplace is no exception. You can find a drawing of the device on the Internet, develop it yourself, or peek a turnkey solution from well-known manufacturers. At the same time, the design of the device itself can be modified according to your preferences.

If we consider how the burner, the firebox for the biofireplace in general terms, is arranged, then it represents a reservoir for fuel, from which the wick for fire is removed to the external area. Bioethanol is poured into the tank, which gradually burns out at the tip of the wick, hidden by decorative elements.

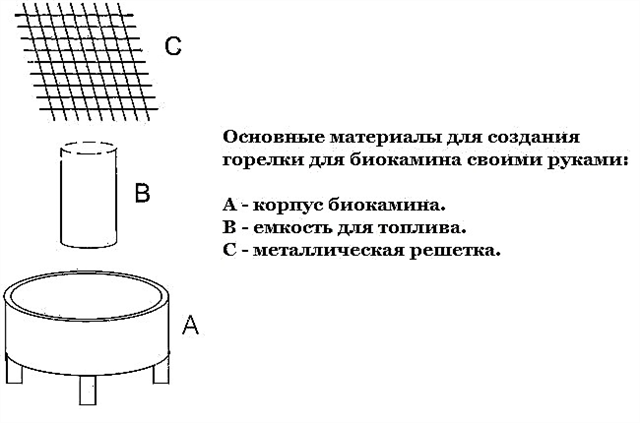

The components of the biofireplace are easy to use, easy to install. All you need to work is:

- A metal tank of the required shape and volume, which will be directly installed inside the biofireplace. The decorative qualities of this metal box are unimportant, since it will still be hidden from view. The basic requirements for it are complete tightness and fire resistance. You can make it of metal yourself, or choose an already finished option.

- To connect the internal and external parts of the fireplace, you need a wick, cord, fabric.

- For an even distribution of fire in a biofireplace, you need a metal mesh. It will become the main one on which you place decorative accessories.

- To protect against fire, a glass screen of refractory glass is required.

- Biofuel will be the main fuel used to operate the device. By the way, biofuels can also be made independently from various alcohols.

To assemble all the elements together, it is advisable to develop a drawing on which the design of the biofireplace burner will be clear to you. In addition, these drawings can be guided in the future, choosing decorative accessories.

To build a bio-fireplace with your own hands, you will need to carry out the following work:

- Assemble the main body of the biofireplace, glue or fasten the protective screen and install on it. The protective screen can be connected with fasteners, or it can be glued, for which a special heat-resistant sealant is used. Note that it dries for at least a day, so work should be done in advance.

- Install a fuel tank in the assembled housing, secure it so that it does not hang.

- Prepare a metal mesh installed on the biofireplace body on top of the fuel tank. If the cells in the grid are too large, you can use several layers stacked in the machine with an offset.

- Lay the wick inside the structure by connecting the tank to the outside of the bio-fireplace.

- Load decorative elements and distribute them on the grid, while hiding the wick of the device from the eyes.

- Pour bioethanol into the biofireplace tank, start the device.

The first start will show if the system is working properly. If not, then it is worth finalizing it; if so, then you can proceed to the full-fledged decoration of the inside and outside of the device.

Fortunately, there are a lot of accessories for bio-fireplaces that can decorate the space inside the device. You can use stones of various textures, colors and shapes, or imitations of firewood and coals, alternative objects. These decorative elements are created from ceramics, which is not afraid of direct fire. Thanks to these accessories, a more complete picture of what is happening in the fireplace is created.

Do not forget about the external surroundings. Firstly, harmoniously shape the body of the biofireplace itself, select the necessary colors, materials, and secondly, organize the space around the appliance, for example, put appropriate objects, such as poker or tongs for working with firewood, a lighter and a device for extinguishing a biofireplace.

Pros and Cons of a Biofireplace

Biofireplace has its advantages and disadvantages. The most significant of them.

- easily ignited and extinguished,

- does not require additional devices, power supply,

- it’s an additional source of heat,

- safe combustion products.

- often the fire in the device is in an open structure, it is not always safe,

- the purchase will cost a decent amount,

- expensive fuel that burns quickly.

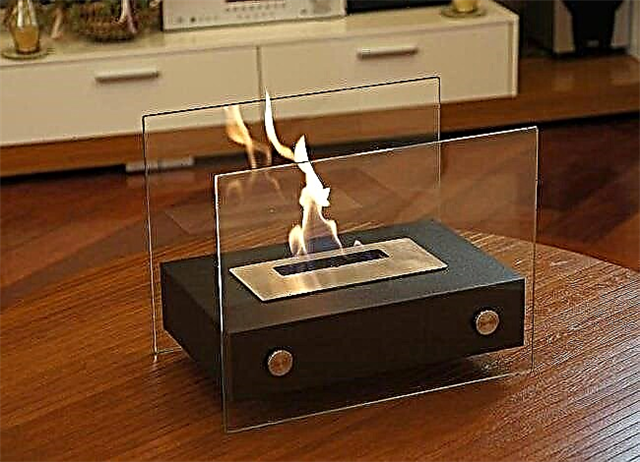

Desktop biofireplace may differ original design decision

Desktop biofireplace may differ original design decision

Burner device for biofireplace

Biofireplace consists of several elements. Each of them has certain requirements, which ensures the safe operation of the device.

The main components of a biofireplace are a body, a metal protective grill and a fuel tank

The main components of a biofireplace are a body, a metal protective grill and a fuel tank

Fuel tank

The main element of a biofireplace is a fuel tank, it is made of metal. No matter how she looks externally, she will still not be noticeable. The main criterion is resistance to high temperatures and tight joints so that fuel does not escape.

As a fuel tank, you can use a regular can

As a fuel tank, you can use a regular can

From the fuel tank to the walls of the portal or the casing there must be at least 10 cm. If several burners are implied, they are placed at some distance from each other, about 5-10 cm.

Housing

The body of the biofireplace should be made of heat-resistant material, it is desirable to process it with paint that is resistant to high temperatures.

The bio fireplace portal can be from:

The metal case is one of the most common solutions.

The metal case is one of the most common solutions.

Fuel

Fire burns due to bioethanol - it is an environmentally friendly liquid from alcohol, which, when burned, emits only carbon dioxide and water. When used in the apartment there is no unpleasant odor.

Liquid fuel is obtained by processing agricultural crops, for example, potatoes. Sometimes the fuel can be gelled.

Typically, fuel is produced in large volume transparent bottles.

Typically, fuel is produced in large volume transparent bottles.

500 ml of fuel is enough for 1.5 hours.

Wick

Internal and external parts are connected by a wick. There are no special requirements for it, as you can take an ordinary lace or piece of fabric.

Ordinary twine can become a match for a fireplace

Ordinary twine can become a match for a fireplace

Metal grill

The metal grill allows you to evenly distribute heat throughout the area. It is also convenient to arrange decorative elements in the form of stones, shells, etc.

The metal grill can be ordered separately or made independently.

The metal grill can be ordered separately or made independently.

Security

The use of a biofireplace can be hazardous to health if a number of simple rules are not followed.

- If the fireplace is large, it is better to install protection around it in the form of a refractory glass.

- The case can be made of any heat-resistant material, usually a metal box.

- Fuel should be filled only during the operation of the fireplace. An alcohol-based liquid will still evaporate if left in the open air. Such regular fumes are harmless.

- Fire can not be left unattended or placed near drafts, fans.

- When assembling the burner body, carefully check the tightness of the joints.

- The distance between flammable objects and the fireplace should be at least 1.5 m. Between other objects at least 1 m.

Types of burners for biofireplaces

Although biofireplaces differ in external parameters, their internal structure is almost the same.

There are only 3 types of burner devices:

The standard biofire burner is simple

The standard biofire burner is simple

Capillary

A capillary burner requires the use of a precisely measured dose of fuel. It is drawn into the burner itself using capillary forces.

She has a number of minuses:

- while the evaporator warms up, there is a smell of alcohol,

- at the beginning of burning, the flame flashes up strongly, but calms down after a few minutes,

- an overabundance of fuel provokes splashes, it can be dangerous at high temperatures,

- in the capillary device there is always a little unspent fuel

- a flap for adjusting the fire is required,

- the filler has to be changed, because it is regularly clogged with combustion products.

The simple capillary torch design can work up to 2 hours

The simple capillary torch design can work up to 2 hours

Gravity

Fuel instantly enters the evaporator. Due to this, the fireplace is set on fire immediately. The fire is held steady, there is no need for a shutter, but it is added to regulate the flame for decorative purposes. The design is quite complex, it is impossible to repeat it yourself.

The fuel in the gravity flow device is used to the end due to the heating of the fuel tank

The fuel in the gravity flow device is used to the end due to the heating of the fuel tank

Types of biofireplaces

Before you begin designing a biofireplace, you should figure out where it will be located and what function to perform.

- tabletop

Compact devices do not take up much space

Compact devices do not take up much space - wall mounted

Wall mounted fireplace harmoniously fits into the living room

Wall mounted fireplace harmoniously fits into the living room - outdoor.

The floor unit is ideal for a large room.

The floor unit is ideal for a large room.

Table fireplaces are usually small, round or rectangular, made of ceramic or metal. The distance from the glass to the burner should not be less than 10 cm.

Wall mounted fireplaces always have an elongated rectangular shape so that they can be easily attached to the wall. The back wall is always made of heat-resistant material, for example, metal. The front part is made of refractory glass.

Outdoor biofireplaces are the largest. Often they are decoratively executed as standard chimney fireplaces. If it’s a regular bio fireplace, it’s just set on the podium.

How to make a do-it-yourself burner for a bio fireplace

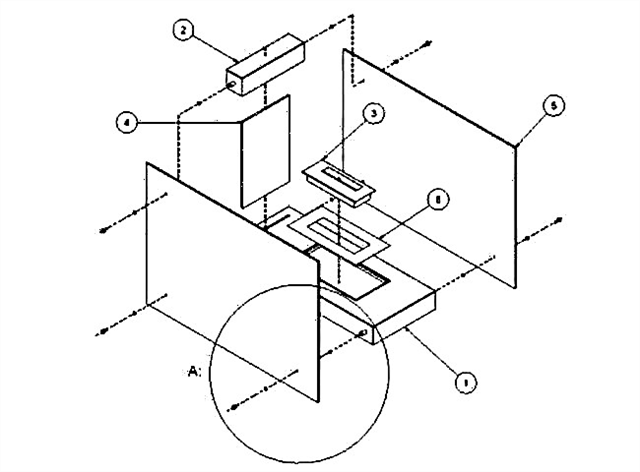

A burner for a biofireplace, a drawing of which must be drawn taking into account all sizes, is assembled from a can, case and wick. Then, if desired, a metal grate, mineral wool, refractory glass, etc. are mounted.

Drawings of the case of bio-fireplaces of wick, capillary and gravity type will help to assemble devices with their own hands

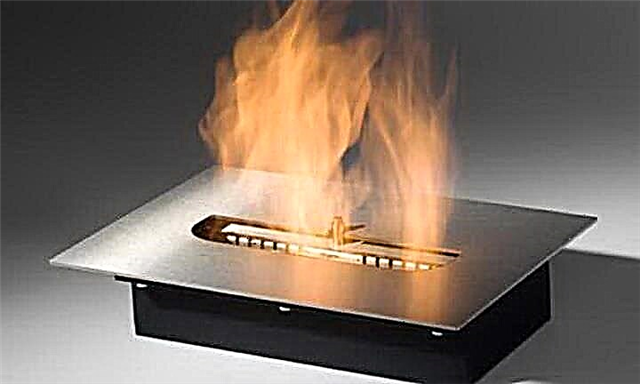

Simple burner

The simplest option is a can burner. Bioethanol is poured into the container. For better heat distribution, you can put a metal grid, for beauty, lay stones on it. The place above the hole is set on fire.

It is good if the fireplace body is metal with double walls.

The simplest burners resemble a can

The simplest burners resemble a can

Filler burner

The method of operation is similar to a simple burner, but mineral wool or glass wool is laid out as a filler. The best option is a white glass wool on an acrylic base, it absorbs liquid well and easily passes vapors.

When filling the container, the cotton wool should not be compacted, it is freely placed in the tank. A metal mesh is installed on top, then fuel is poured. Vata quickly absorbs bioethanol and prolongs its burning time.

Mineral wool burners for biofireplace - one of the more complex design options

Mineral wool burners for biofireplace - one of the more complex design options

Decoration of a fireplace burner

Decorations neatly hide the elements of the burner and help to make a stylish interior item out of an ordinary fireplace.

Materials for decoration:

- any natural stones, pebbles,

- ceramic models of logs,

- seashells

- dummies of coals made of glass ceramics.

Decor elements depend on the interior in which the fireplace will be located.

For rooms with a bright interior, a combination of shells and white rounded stones is suitable.

The fireplace, decorated with white stones, is suitable for the living room in modern style

The fireplace, decorated with white stones, is suitable for the living room in modern style

For a classic living room, it is better to choose an imitation of logs or coals. Most often, the fireplace is decorated with different natural stones.

Imitation fireplace with chimney

Imitation of a real fireplace with a portal is very popular. Such a burner design for a biofireplace will not differ from a conventional tin can design.

The portal is made of drywall, metal profile. Painting is carried out with acrylic dye with mineral pigment. The arch must be treated with heat-resistant enamel, this will protect it from fire.

Such portals still have a risk of ignition; when operating a biofireplace, you should not depart from the structure.

The necessary conditions

A burner drawing for a biofireplace of various complexity can be easily found on the Internet. Yes, and draw it yourself, too, is not difficult. However, before starting work, it is necessary to understand that there are some requirements for the device that must be observed in order for the craft to turn out not only beautiful and stylish, but also safe.

- Saving due to cheap material should not be - this is not the option. Fire is a very insidious element, capable of getting out of control even with the slightest inaccuracy.

- The ideal, and almost the only solution is to use a thick-walled sheet of stainless steel, from which to cut the necessary parts, and then tightly connect them.

- Do not rush and withstand the required time necessary for hardening or drying of the fastening components.

- After completing work and before first use, carefully check for any bumps, scratches or chips.

Varieties

With all the apparent diversity of biofireplaces, they differ by and large only in appearance. Inside, they are built on almost the same principle. Nevertheless, a burner for biofireplaces can be of two types.

- First: the usual container, under which you can adapt a simple tin can. Unpresentable view then decorate. Financial costs are practically not required, but this option has its own some inconveniences. The flame will be uncontrollable. In the sense that it will be possible to repay it only by closing it with something from above, which will lead to the appearance of a sharp unpleasant odor, but it is generally impossible to reduce or increase it. Odor can only be avoided in one way - to wait until the fuel burns completely.

- The second burner option is a fuel tank equipped with a special shutter. You will have to spend it tangibly, but there will be no smells and problems with adjusting the flame. To make such a burner yourself is possible only with high-precision tools and high-quality materials.

Given all of the above, it is better to sit, think carefully and try to compose the first and second option, depending on your capabilities. The scheme should not be too complicated, but taking into account all security measures.

DIY fireplace burner

The burner and the fuel tank are essentially the same thing. Just before you start, you need to decide what exactly you want to get in the end. A stylish bio-fireplace with the ability to ignite and extinguish it at your discretion, or just to let the flame dance until the fuel runs out.

In any case, you will need to work:

- Metal tight container with walls thick enough so that they do not deform when heated.

- Metal grill, if possible with small cells.

- The base on which the burner itself will be installed.

- Refractory glass.

- Wick.

- Fuel.

- Step-by-step instructions downloaded from the Internet or compiled independently.

Ethanol should be used as fuel - alcohol prepared on the basis of plant components. It is absolutely environmentally friendly, has no color or smell, and when burned it emits carbon dioxide, identical to what a person produces when breathing. As a wick, a regular shoe lace is suitable.

Further, the algorithm of actions is approximately the following:

- Inside the base, which can serve as another metal box, we glue the refractory glass on the sealant so that it protrudes slightly above the edges. Although everyone can set the height of the glass for himself.

- Install a tank for fuel. It can also be fixed with sealant to the bottom of the base.

- We lay a metal grate on top. If the cells are too large, you can put the grid in several layers.

- Fill the burner with fuel.

- Lower the wick.

- We decorate to hide unpresentable details and add refinement and style to the resulting bio-fireplace.

As you can understand, to build just one burner is not enough. So it’s better to immediately tune in to work that will require some preparation, diligence and some amount of free time.

We decorate a biofireplace

The main source of comfort for a biofireplace, of course, is a living flame. But it is one thing when it is knocked out of a tin can, and another when decorating objects are stylishly and elegantly laid around it.

Most often, biofireplace burners are decorated with smooth stones or pebbles, selected in color, shape and size. In no case can they be painted. Firstly, when heated, even if it doesn’t light up, it will begin to emit an absolutely unnecessary smell. So it’s better to spend some amount of time and pick up stones that suit your artistic taste. Moreover, at any time they can be changed.

The second version of the decor is an imitation of firewood. You can buy them in specialized stores, along with fuel.

The biofireplace itself, if it turned out to be large enough, can be glued with a special decorative heat-resistant tile.

Well, the top of perfection is to buy in the same store a special sound device that simulates the crackling of logs in the hearth.

You can enjoy the fireplace, in which the living flame dances, endlessly. And when it is created with your own hands, a sense of pride will also join in the pleasure and coziness, which is also very important.

Original burner

We have already examined how to make a burner for a biofireplace as close as possible to that produced at the enterprises, but there is another embodiment that allows you to make a practically one-time biofireplace in a couple of minutes.

To do this, an alcohol tank is created that is directly connected to the combustion area by making holes in the lid. The tank is filled with mineral wool and filled with alcohol. To create a small burner, you can take an ordinary iron can with a lid. Further, the area above the holes is set on fire, and we have at our disposal a simple, small bio-fireplace. Such a device of a biofireplace burner will allow you to create a romantic atmosphere with your own hands in just minutes.

It is glass wool that should be used as filling, since the basaltic version will not work. Glass wool perfectly absorbs liquid, passes its vapor through itself, does not contain formaldehydes and, of course, does not burn.

Choose cotton-like white glass wool, as this option is as environmentally friendly as possible. made on an acrylic basis. The density of the wool does not play a big role, but it is desirable that it be soft. When filling the tank, do not tighten the filler strongly.

We hope that now you understand how to make a burner for a bio fireplace with your own hands, and you understand that there is nothing particularly complicated in this process. The most important thing is to show imagination, work out the safety of the device and take into account the nuances of the docking of its elements during assembly.

Compact devices do not take up much space

Compact devices do not take up much space Wall mounted fireplace harmoniously fits into the living room

Wall mounted fireplace harmoniously fits into the living room The floor unit is ideal for a large room.

The floor unit is ideal for a large room.